Waterjet excels at industrial tasks due to its scalability. While productions or processing are all limited by simple physics, waterjets are natively flexible enough to adapt to various industrial tasks. Companies utilize waterjets to cut metal blocks which can weigh a few tons. Companies also use waterjet to cut a small block of wood weighing no more than a pound. Through this flexibility, waterjets are able to scale its production upon demand and provide a solid cutting solution.

Traditional cutting methods often use a solid or sharp object to cut through another solid object. This has been the tried and true method for centuries ever since man invented tools. While this method gets the job done, there may be side effects that a business may have to account for. The material being cut may be too brittle that applying force with another solid object might shatter it. When you're using a motorized saw, the friction created between the blade and the material being cut may produce enough heat to damage either the saw or the material.

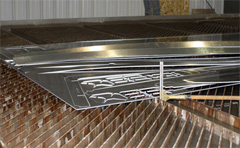

Waterjets do make contact with target materials but the contact is made in a very different way. Ultra high pressure pushes the water down a pin hole nozzle, creating extreme amount of force on a small area. This causes the water to erode away the solid object it comes in contact with, eventually creating a cut as the object or the nozzle moves around. Materials which are being cut by waterjets are basically disintegrating away. No damage is done to the material as a whole since no additional forces are applied to the material. There is no negative impact to the material and there is no friction. Waterjet cutting is one of the best ways of cutting a material without having adverse effects on it.

In fact, waterjet cutting is perhaps the most efficient cutting method when it comes to material preservation. Waterjets can cut thinly as a human hair, which means that only a miniscule portion of the material will be wasted. This allows businesses to get more out of the materials being cut. While such savings may seem small in a single cut, projects after projects will eventually build up to create a significant amount of savings.

Through versatility and efficiency waterjet cutting has become a valued services in many business spheres. A single waterjet machine can be tweaked and configured to handle multitude of tasks, meeting almost every cutting needs that a business may have. Waterjet process can also be fine tuned to increase speed or quality, offering businesses a valuable option. Through waterjet cutting, businesses have a say on how their project is going to be planned out, as opposed to changing the scope of a project due to inflexible solutions.